Bitumen Emulsion Equipment

|

USB-2 Bitumen emulsion unit 2 m3/hour production capacityBitumen emulsion equipment designed for production both anionic and cationic bitumen emulsions with production capacity 2 m3 per hour. The unit is designed for operation at asphalt concrete production facilities. It can be operated either outdoors under canopy or indoors. The unit is equipped with temperature and pressure sensors.

|

|

USB-2 Bitumen emulsion plant 8 m3/hour production capacityUSB-2 bitumen unit is designed for production both anionic and cationic bitumen emulsions, which are used in road construction as follows:

|

|

FB Bitumen filterThe FB bitumen filter is engineered to eliminate solid impurities from bitumen and similar non-corrosive fluids. It is crafted for seamless integration into procedures related to the input, storage, and extraction of conventional or modified bitumen, bitumen emulsions, and other highly viscous liquids that necessitate heating. Equipped with two filter cartridges, this filter ensures uninterrupted operation. Additionally, it incorporates temperature and pressure sensors to ensure reliability and safety. |

|

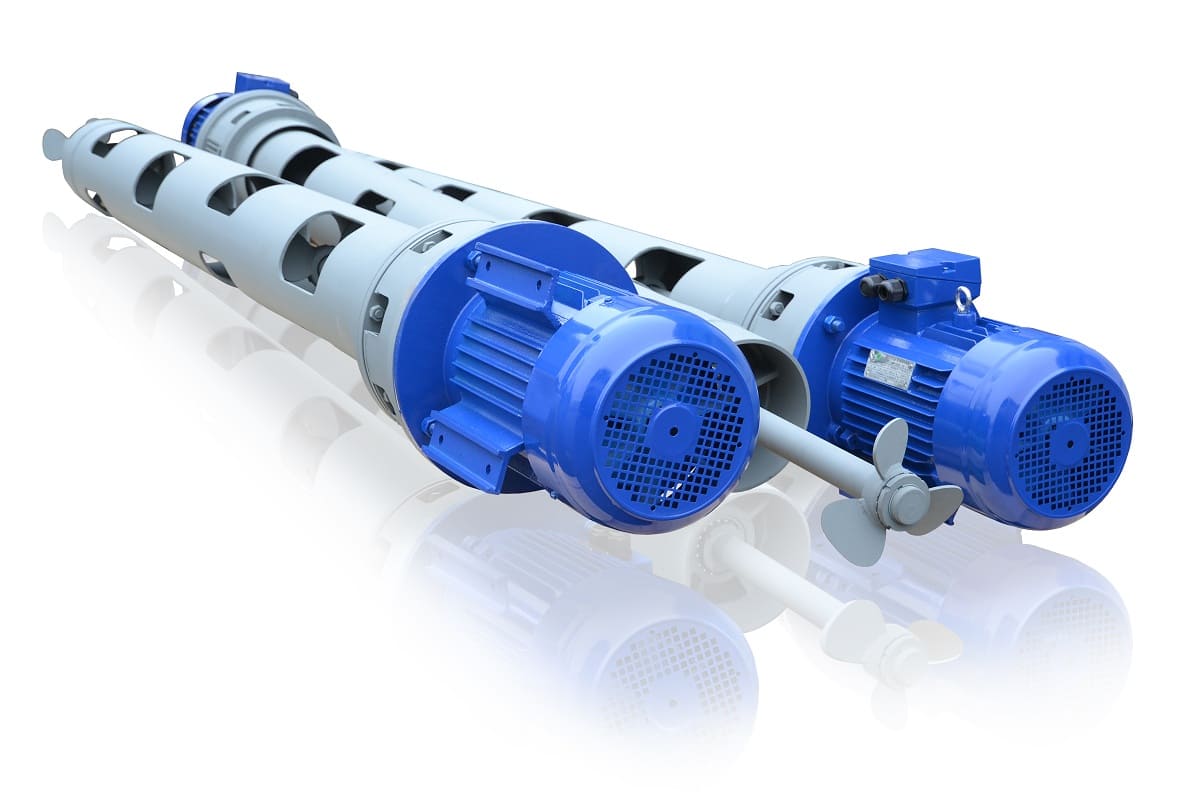

Impeller Stirrer USB-6The USB-6 impeller stirrer is specifically engineered for effectively mixing liquid layers within containers or tanks, serving a variety of applications including the production of different emulsions and suspensions, such as antiseptics and disinfectants. |