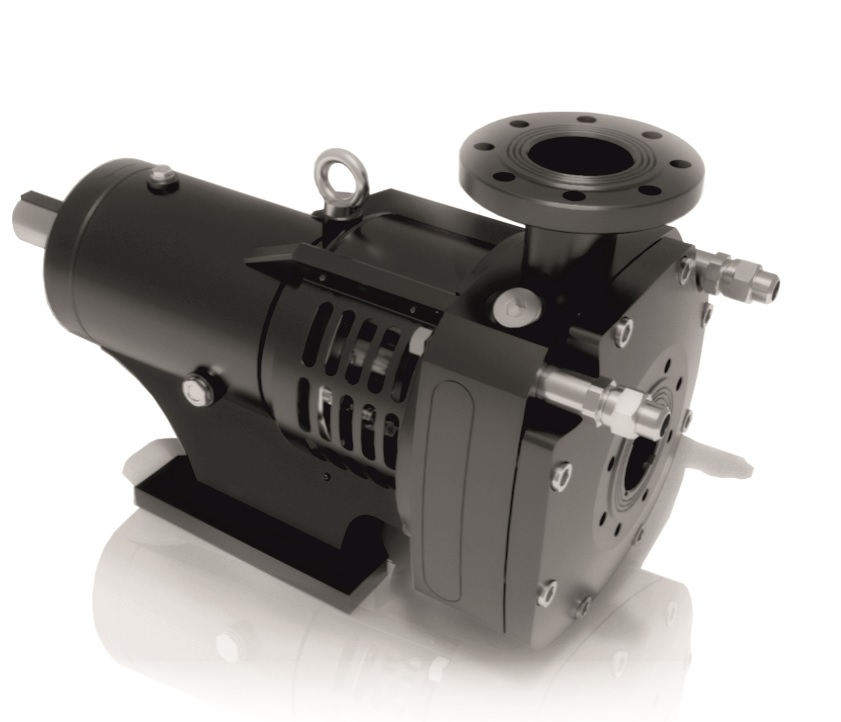

Colloid mill CLM-10/20

The CLM-10/20 colloid mill is engineered for inline homogenization and emulsification of liquid products, particularly thick slurries subjected to high shear stresses, with a primary focus on polymer-based bitumen modification.

This colloid mill is versatile, finding application in the preparation, dissolution, and processing of various products across different industries.

Design and Operating Principle

The operation principle of the CLM-10/20 colloid mill revolves around a rotor/stator system. Comprising concentric tool rings like cutters and knives with specialized configurations of grooves and holes, this system ensures optimal mechanical impact on the processed product. In the operational state, the rotor (moving tool) and stator (stationary tool) tool rings align coaxially and rotate contact-free at high relative speeds of up to 52 m/s, facilitated by axial and radial gaps. Product ingress occurs through the axial bore of the stator (product inlet), traverses the rotor/stator system, and exits radially (product outlet) from the mill housing. Within the rotor/stator system, the product undergoes intricate hydrodynamic processes, experiencing changes in shear stresses, shear forces, and flow velocity. Enhanced contact surfaces of chemical agents expedite chemical reactions, leading to intense dispersion, emulsification, homogenization, grinding, and pulverization of the processed product.

SPECIFICATIONS

| № | Specification |

Value |

| 1 | Unit capacity, m3/h (gpm) |

10…20 (44… 88)* |

| 3 | Operating temperature, °С (°F), not more than |

200 (392) |

| 4 | Maximum pressure, bar (psi), not more than |

20 (290) |

| 5 | Product operating volume, L |

flow |

| 6 | Shaft seal type |

packing (mechanical) |

| 7 | Rotor/stator tooling type |

chamber |

| 8 | Replaceable knife kit |

optional |

| 9 | Knife axial gap (preset), mm (in) |

0.2…2 (8·10-3… 8·10-2) |

| 10 | Knife radial gap, mm (in) |

0.3 (10-2) |

| 11 | Knife tip speed, m/s (mph), not more than |

52 (116) |

| 12 | Mill shaft and bearing rotation speed, rpm |

4,500 |

| 13 | Electric motor shaft rotation speed, rpm |

3,000 |

| 14 | Drive power, kW |

75 (90) |

| 15 | Power voltage, В |

custom |

| 16 | Dimensions, mm (in), not more than: | |

| -length |

1,200 (47) |

|

| -width |

1,000 (39) |

|

| -height |

850 (33) |

|

| 17 | Weight, not more than, kg (lb) |

900 (1,985) |

* – depending on the product (liquid).

ADVANTAGES

- Versatility across Industries: The mill finds application in various industries.

- Compact Design: It boasts compact sizes suitable for different settings.

- Customizable Tooling: Depending on the tasks, the mill can be equipped with various rotor/stator tooling types and shaft seals.

- Durable Construction: The wetted portion and components of the mill can be crafted from structural-grade steel, stainless chemical-resistant steel, and food-grade steel.

- Indoor and Outdoor Operation: It can be operated both indoors and in sheltered outdoor spaces.