Webinar “Production of Modified Bitumen: the Modern Approach”

Webinar “Production of Modified Bitumen: the Modern Approach” Dear associates! You are invited to participate in another free GlobeCore webinar themed as “Production of Modified Bitumen: the Modern Approach” which will take place on July 21–22, 2021. At this webinar, we will discuss the following matters: advantages and special features of using modified bitumen; technical specifications and quality of road bitumen; technology andRead More

A New Bitumen Emulsion Complex Commissioned in the Capital of Ghana

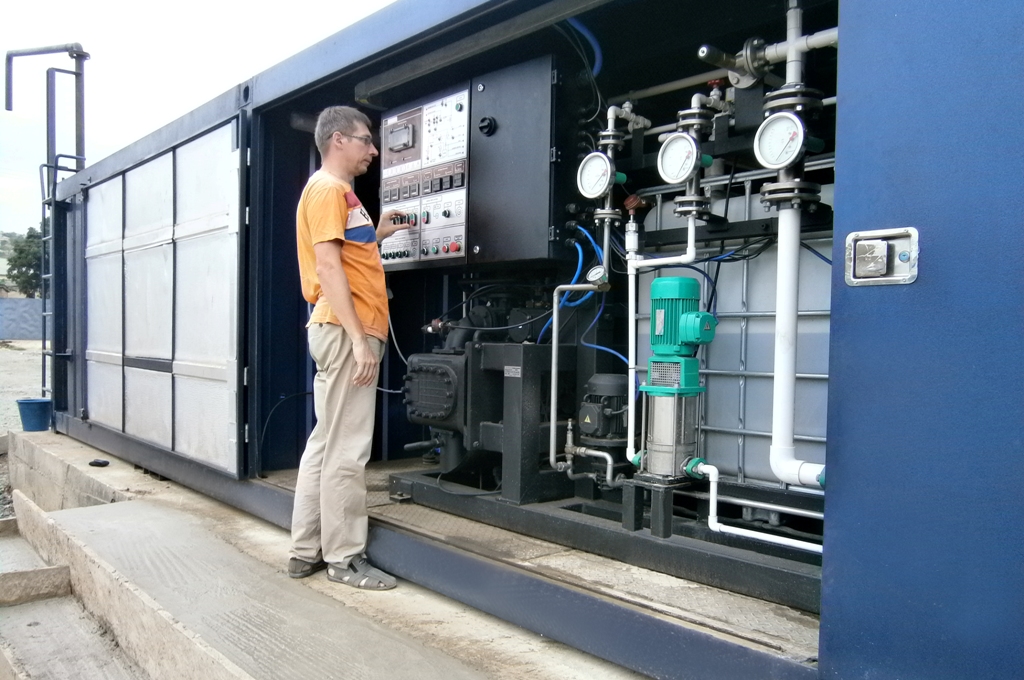

A New Bitumen Emulsion Complex Commissioned in the Capital of Ghana For a month (8 June to 8 July this year), GlobeCore engineers visited Accra (Ghana). The engineers assisted with assembly and commissioning of a full scale bitumen emulsion production complex there. An important part of the complex is GlobeCore equipment for the production of cationic or anionic bitumen emulsions. Note that our company also manufacturesRead More

Commissioning of a UVB-1 Unit in Myanmar

Commissioning of a UVB-1 Unit in Myanmar On 8 – 13 July 2018, GlobeCore officers visited Myanmar. The visit was to commission an 8 cubic meter per hour UVB-1 bitumen unit and to train client personnel. This unit is designed for production of cationic and anionic bitumen emulsions, and will be operated in a suburb of Yangon. The UVB-1 features semi-automatic operationRead More

GlobeCore equipment started in Kazakhstan

GlobeCore equipment started in Kazakhstan Road traffic grows rapidly by the year – along with the physical loads on the road top. This requires the use of economical high quality materials and reliable technologies for road construction and repair. Bitumen emulsion fit the bill perfectly, with several significant advantages over the usual “hot” technologies (efficient use of energy, extension ofRead More

Increasing productivity of existing bitumen-emulsion plants

Increasing productivity of existing bitumen-emulsion plants Dear Valued Customers! We would like to remind that GlobeCore provides an opportunity to increase the existing bitumen-emulsion plants performance by introducing an additional block. It has the potential benefits in the form of efficiency and functionality. It allows to raise the productivity of both GlobeCore plants and plants of other manufacturers. One such projectRead More

Bitumen modification equipment

Bitumen modification equipment Bitumen modification equipment GlobeCore equipment produces modified bitumen for: Cement protective layers and crack sealants Surface treatments and concrete top layers Viscous road bitumen Mastic asphalt and porous asphalt Thin and very thin layer coatings Production capacity of bitumen modification unit from GlobeCore UMB-L Minimum production in one cycle 12 litre/hour UVB-2 Minimum production capacityRead More

Bitumen emulsion production equipment

Bitumen emulsion production equipment Bitumen emulsion production equipment GlobeCore equipment produces bitumen emulsions for: Treatment of road surfaces Undercoat Patching Cold asphalt mix Slurry Seal Production capacity of bitumen-emulsion plants from GlobeCore UVB-1 20l/hour production capacity UVB-1 1m3/hour production capacity UVB-1 2m³ /hour production capacity UVB-1 8m³ /hour production capacity Advantages of GlobeCore Bitumen EmulsionRead More

New adaptable in design UMB-6 plant: provides high quality modified bitumen

New adaptable in design UMB-6 plant: provides high quality modified bitumen Modified bitumen is widely used in road works for construction and repair of road surfaces, also in waterproofing buildings and structures, roofing and pipeline protection. GlobeCore design department has developed a new UMB-6 plant for mixing in circle of modified bitumen (productivity 6 m3 / h). The design and dimensions of this equipment were adaptedRead More

UVB-10PK Bitumen Complex Commissioned in Ghana

UVB-10PK Bitumen Complex Commissioned in Ghana GlobeCore team successfully completed all works according to the contract to supply and commission a UVB-10PK bitumen complex, including operating personnel training. The main feature of this equipment is versatility. The UVB-10PK can accept and prepare bitumen for further use, produce, store and output all types of bitumen emulsion. This optimizes the time andRead More

GlobeCore presented a seminar In Quito

GlobeCore presented a seminar In Quito During 2 days, May 3-4 in Quito (Ecuador), GlobeCore held a seminar presenting its equipment The event was attended by representatives of the electricity industry from many countries, including Peru, Bolivia, Argentina, Colombia, Costa Rica and El Salvador. The seminar covered the following questions: General information about GlobeCore; Modern technologies in cleaning and regeneration ofRead More

CMM-4/7 started up in Estonia

CMM-4/7 started up in Estonia 10 апреля 2017 года специалисты GlobeCore запустили установку КИМ-4/7 в Таллинне (Эстония). Это оборудование используется предприятиями, занимающимися установкой, ремонтом и эксплуатацией силовых трансформаторов для дегазации и фильтрации изоляционного масла. Также установки могут использоваться для нагрева маслонаполненных электроприборов горячим маслом, для вакуумной дегидратации и вакуумирования трансформаторов. Термовакуумная обработка КММ-4/7 позволяет получить следующие параметры масла: влажность поRead More

Improving Bitumen Properties with Additives

Improving Bitumen Properties with Additives Bitumen properties. Petroleum bitumen is widely used in construction. It is due to the versatility of this binding material. And it is successfully used in road works, roofing, waterproofing, sealing, for protection of pipelines, canals etc. But when used in cold weather conditionsб bitumen becomes brittle, which leads to the rapid failure of bitumen coating.Read More

Bitumen Roofing Materials

Bitumen Roofing Materials Bitumen Roofing. Bitumen has been used roofing for many years. Bitumen-impregnated cardboard is the most popular due to its relatively low cost and versatility: this material can be used not only for roofing, but also for waterproofing. Rolled bituminous materials absorb water quite well and cannot guarantee completely watertight seals. So roofs are made ofRead More

Modification of Bitumen as a Method to Improve Performance

Modification of Bitumen as a Method to Improve Performance Modification of Bitumen. The performance of bitumen in road construction can be improved in two ways. First, to improve the production process. Second, to mix bitumen with special additives. At the production stage, tar oxidation is often improved. IT is difficult to do without the process, but it alone is not sufficient. Improving tar oxidationRead More

Production of Modified Bitumen

Production of Modified Bitumen Production of Modified Bitumen. Traffic intensity has grown significantly in recent decades. Each year, the number of motor vehicles grows along with the load on the road top. This results in deformation of the road surface, which require increased number of unscheduled repairs. The situation can be addressed by improving thermal stability, brittleness and agingRead More

GlobeCore presented its equipment at Gulf Industry Fair in Bahrain

GlobeCore presented its equipment at Gulf Industry Fair in Bahrain February 7-9, 2017 Bahrain International Exhibition Centre hosted a Gulf Industry Fair 2017. The fair was held in Manama (the capital of Kingdom of Bahrain) and brought together the leading manufacturers of equipment for energy industry, environmental protection, metallurgy, etc. The exhibition was first held in 2008. Since then it was visited by more thanRead More

GlobeCore Cooperation With the US Power Industry

GlobeCore Cooperation With the US Power Industry GlobeCore strives to participate in all possible projects to replace traditional energy sources with alternatives. Some of the services GlobeCore offers our clients is the sales of equipment to process electrical insulation oil and servicing power transformers, as well as rentals of this equipment. It was the latter option that was chosen by one ofRead More

Yet another product Expansion: Bitumen Emulsion Sprayer RBE-0,2

Yet another product Expansion: Bitumen Emulsion Sprayer RBE-0,2 GlobeCore is delighted to inform of yet another expansion of products. From today representatives of road works companies can purchase RBE-0,2 bitumen sprayers. This bitumen spraying equipment is designed for covering surface with bitumen emulsion by spraying it during asphalt repairs and maintenance of sections of small road and other objects of road facilities. InRead More

Polymer modifiers for bitumen: caoutchoucstyle=”text-align: justify;”>Various polymers can be used for bitumen modification, including caoutchouc. The key property of caoutchouc is stretching 2-10 times with application of a stretching force and return to initial state afterwards. This is due to the structure of caoutchouc. Macromolecules of this substance are coiled, therefore, interaction between them is much weaker than intermolecularRead More

SBS Based Polymer Modified Bitumen Production ProcessModified bitumen is produced in asphalt-concrete plants by special units. To produce polymer-bitumen binders of proper quality the following materials are used: viscous road bitumens and block copolymers of SBS type, surfactants and plasticizers (if required). When choosing equipment and production capacity, technical and economic parameters of production, as well as the required production volumeRead More

Polymer Bitumen Roofing MasticThe modern roofing material market is quite diverse. Nevertheless bitumen-polymer mastics attract attention among other materials. Physically, this compound is a liquid, viscous and uniform mass, which after surface application hardening becomes solid coating. Polymer bitumen roofing mastic is mostly used for construction and maintenance of roofs, as well as waterproofing. Depending on application mode,Read More

Modifiers and types of roofing bitumensEither air blown bitumen or modified bitumen can be used for production of bitumen shingles. The question is which material is better. Modified bitumen is a mix containing various modifiers for performance improvement. In recent years there is an emerging trend: manufacturers of roofing materials prefer modified bitumens to air blown bitumens more often thanRead More

Materials for soft roofingUntil recently rolled roofing materials were the most popular. They attracted customers by their relatively low cost. Besides, this roofing material did not have many alternatives. The situation has changed with the appearance of heat hot roofing materials, liquid rubber and roofing bitumen. Modern roofing materials have a more complicated structure, new types of baseRead More

Roofs based on polymer or latex solutionsSometimes a rolled roof cannot be constructed. Originally, the alternative was proposed in 1957 in the United States. Solutions of polymers were applied layer by layer, creating a solid coat after settling. Specifically, a solution of polychloroprene rubber and chlorosulfonated polyethylene with fillers and vulcanizing agents are applied to roof base. In both cases, whenRead More

SBS-modified roofsRoofs have been suffering from extensive wear during the last decade. This creates problems not only for the owners of the roofs, but also for the government, which must address the problems of efficient use of resources and energy and to ensure longevity of structures. Installation of roofs in cold climate faces some difficulties dueRead More

Application of polymer-bitumen and polymer membranesPolymer-bitumen and polymer membranes can be applied by mechanical, ballast or glue technique. Mechanical application is performed by special fittings. When sheets of the sealing are applied, they completely isolate the base from atmospheric factors. However, high winds may tear the waterproofing layer off the roof. The maximum wind load defines the following factors: applicabilityRead More

Roofing membranes

Roofing membranes Roofing membranes is a relatively new material for roofing operations, which has been increasingly popular in the market. This is due to the combination of good customer experience and technological properties. First of all, is is the improved durability and faster application. Due to the various roll width, it is possible to perform roof waterproofingRead More

Bitumen-polymer grout materials

Bitumen-polymer grout materials Bitumen-polymer grouts are represented by roof grout used both as a separate roofing material and as a component of seamless roofing system. Usually, grout is applied on a prepared surface in liquid form, and afterwards dries into damp-proof film with no joints or seams. Bitumen-polymer grout consists of the following components: thermoplastic polymer (polymeric petroleumRead More

Bitumen-polymer materials for roofing

Bitumen-polymer materials for roofing According to the commonly accepted classification, there are three groups of modern roofing materials for rolled-roofing: materials based on bitumen, complex composition bitumen-polymer materials and fully polymer materials based on polymeric petroleum resin or rubber. Bitumen-polymer materials, as the name implies, consist of bitumen and polymer components. However, the amount of the latter usually doesn’tRead More

Modified Rolled Materials

Modified Rolled Materials Modified rolled materials for roofing are produced of reinforced base (Fiberglass mats, glass fabric or polyester), bitumen and polymer modifier. While choosing the underlying material, keep in mind that fiber cloth has high tensile strength, polyester has much better specifications but is also much more expensive. Its durability is similar to that of glass fiber,Read More

Bitumen Modifiers For Roofing Applications

Bitumen Modifiers For Roofing Applications To improve properties of bitumen for roofing applications, three modifiers are used most often: atactic polypropylene (APP), styrene butadiene styrene (SBS) and ethylene-propylene-butene (EPB). Bitumen, modified with APP, does not have disadvantages characteristic to common bitumen materials: low flexibility at subzero temperatures and aging tendency. Atactic polypropylene is an elastic material with similar properties asRead More

Modified Bitumen for Roofing and Waterproofing

Modified Bitumen for Roofing and Waterproofing Currently the primary method of modifying bitumen for roofing and waterproofing applications is the introduction of polymer additives. Such approach allows to significantly improve flexibility at subzero temperatures, improve heat endurance, aging resistance, as well as fatigue durability. In most cases. up to 30% polymer is enough for modification of bitumen. Еhe following substances canRead More

Laying of Polymer Bitumen Roofing

Laying of Polymer Bitumen Roofing Application of roofing made of bitumen-polymer materials is performed on a solid base at slopes not exceeding 50º. Technically, this operation can be performed either by gluing or burning heating. For the gluing method, special mastic resins are used. Polymer bitumen materials can be laid on the surface, in spots, in stripes, etc. “Briefer” roofRead More

Components of bituminous roofing materials

Components of bituminous roofing materials Bituminous roofing material is more like a general concept meaning flat, membrane roofing, shingles, rolled roofing materials, etc. Speaking about the chemical composition of modern bituminous roofing, it may include either air blown or modified bitumen. Until recently, air-blown bitumen was predominantly used. It may be explained by the relatively low cost and simplicity ofRead More

Bitumen-polymer rolled materials

Bitumen-polymer rolled materials Bitumen-polymer roll materials are used in roofing operations. Their contents include modifiers (usually polymers). The modifiers help to avoid some of the disadvantages typical for bitumen materials. The base of bitumen-polymer materials is often made of glass fabric, fiber glass mats or elastic polymer fibers. Regulatory documents specify durability and stretching as quality factors forRead More

Shingles

Shingles Appearance of bitumen-polymer materials gave start to principally new construction materials with higher economic and environmental efficiency. In terms of roofing, we need to mention the so called shingles, also known as roofing slates. Slate tiles, cut of polymer-bitumen material, allow light and good-looking roofing on 12% slopes. Shingles ensure long life high elasticity whichRead More

Methods of Bitumen Modification For Roofing Materials

Methods of Bitumen Modification For Roofing Materials Modified bitumen is a material with properties changed by injection (addition) of special substances (modifiers). It is used in road and civil construction. In the latter case, modified bitumen is an element of roofing. Atactic polypropylene (APP) and artificial rubber Styrene Butadiene Styrene (SBS) are used most often for bitumen modification. APP is used toRead More

Polymer-bitumen Materials For Roofing

Polymer-bitumen Materials For Roofing Emergence of polymer-bitumen materials was an important innovation in the development of roofing technologies. Unlike products of similar purpose, bitumens modified with polymers are corrosion-proof and retain their chemical stability. Due to the above, roofing service live can be significantly extended. In this case glass-fabric, fiberglass mats or polyester are used as a base. PolyesterRead More

The History of Modified Bitumen Development

The History of Modified Bitumen Development Modified bitumen is a substance that has passed the procedure of its properties improvement by means of adding special additives (modifiers). Bitumen modifier is selected on the basis of the functions which should be performed by the pavement laid on the basis of this material. Among the most common bitumen modifiers the following should beRead More

Roofing And Waterproofing Bitumen Emulsions

Roofing And Waterproofing Bitumen Emulsions Creating durable, cost-effective, environmentally friendly roofing and waterproofing materials is one of the most urgent tasks of civil and road construction. In the past years, a variety of methods were used to try to solve this task, until the application of bitumen emulsions came to the fore. Their popularity in roofing, waterproofing and road worksRead More

How to go into modified bitumen manufacture business?

How to go into modified bitumen manufacture business? Probably everybody has had the idea to start his own business at least once. However, most potential businessmen face hardship even at the first stage when they need to choose a field of future activity. It is clear that one should pay more attention to new and untapped business. In this case chances of successRead More

How to Start Bitumen Emulsions Business?

How to Start Bitumen Emulsions Business? Of course, everyone thought about starting a business at least once in their life. The prospect of working totally for yourself, not for someone else, is tempting. But only some dare to open their own business. Some do not have sensible ideas, some are afraid to take risks and to take loans, although the financialRead More

Modification Comes into Play Improving Properties of Bitumen

Modification Comes into Play Improving Properties of Bitumen The term “bitumen” is derived from the Sanskrit word “jatu”, and then Latin “gwitu-men” which at that time meant pitch-producing (referring to resinous trees). Ancient Greeks used a slightly different word – “asfales”, which meant “certain”. The latter fact is not accidental, because bitumen is the most ancient building material of all currently known toRead More

Roofing with Modified Bitumen

Roofing with Modified Bitumen The roof is one of the most important elements of the building, ensuring protection against adverse weather conditions and creating aesthetic appearance. Therefore, the design of the roof is very important. No less important is the selection of roofing material; in fact, it forms the future protective coating. In building construction literature, there are severalRead More

What is modified bitumen?

What is modified bitumen? Construction of new facilities and installations requires quality materials. It is one of the requirements for obtaining durable structures serving humanity with good faith and fidelity for years. But the reality is that not all construction materials fully comply with these requirements. This especially concerns road construction. The total length of roads in the worldRead More

Preparation and Properties of Modified Bitumen

Preparation and Properties of Modified Bitumen Modern road construction places high demands on the quality of materials. This is especially true for the binders used in preparation of asphalt mixtures. Pavements made from traditional bitumen can not cope with modern density and intensity of traffic. Scientists assess the durability of pavements with bitumen-mineral composition, at only 50-70% of normative durability. LowRead More

Modified Bitumen

Modified Bitumen The progress of humanity is linked with construction of new objects, new networks, etc. In recent years, the scale of construction reached the highest levels. This also applies to roads. Every year the traffic load on them increases, which puts extra demands on construction materials. First, they must be strong enough. Second, they must withstandRead More

Choice of Modified Bitumen Roofing

Choice of Modified Bitumen Roofing One of the most important elements of a building is the roof. Its function is the protection from rain, heat, cold, snow, pollutants, dust, solar radiation, etc. But in most cases the roof does not only have a protective function. In some ways, it is a “headdress” of the building, a part of its image.Read More

SBS-Polymers

SBS-Polymers The first synthetic thermoplastic materials entered the market in the middle of the last century (1965). The SBS-polymer name comes from “styrene- butadiene-styrene”. This material has a chemical structure with elastic internal block. This is why SBS-polymers are perfect to be mixed with bitumen. Polybutadiene chain is formed as a result of such interaction. CharacteristicRead More

Experts of GlobeCore Upgrad Plant UMBP-22

Experts of GlobeCore Upgrad Plant UMBP-22 GlobeCore anticipates the needs and preferences of its customers – by producing new equipment and upgrading the existing ones. The latest achievement is– an upgrade of bitumen modification plant UMBP-22. Despite the cost of modified bitumen being more expensive than the cost of usual bitumen its use is practical for the following reasons: temperature resistanceRead More

Modification of BitumenGood road condition is the key to successful operation of many domestic industries. Starting from high quality transportation of goods to the comfort of passengers – all depend on the stability of the roads. Existing materials for road construction provide good quality of road surface with long service life. But with the intensity of roadRead More

Application of modified bitumen in airport construction

Application of modified bitumen in airport construction A runway is the most important part of any airport. Runways can be unpaved, gravel, asphalt or concrete. Unpaved runways cannot be operated in rainy weather, making the use of such facilities quite limited. Considering the loads and the high pressures on the runway, asphalt mix or concrete is mostly used for modern runway construction.Read More

UVB-1 Unit Commissioned As a Part of Bitumen Emulsion Plant in Zimbabwe

UVB-1 Unit Commissioned As a Part of Bitumen Emulsion Plant in Zimbabwe In the end of April 2016 a bitumen emulsion production commissioning ceremony was held in Zimbabwe. This event was so important that the minister of transport and infrastructure, Mr. Yorama Gumbo, attended it personally. The base of the new production line is a UVB-1 unit produced by GlobeCore. The plant will produce up to 10Read More

Modification of Road Bitumen with Polymers

Modification of Road Bitumen with Polymers Road Bitumen with Polymers The first patent for modifying bitumen with natural rubber was registered almost 170 years ago. Ironically, it took another 150 years before the modified road bitumen has taken a worthy place in road construction. There were a couple of reasons for this.. Firstly, the traffic loads on roadway are ever-increasing. Secondly,Read More

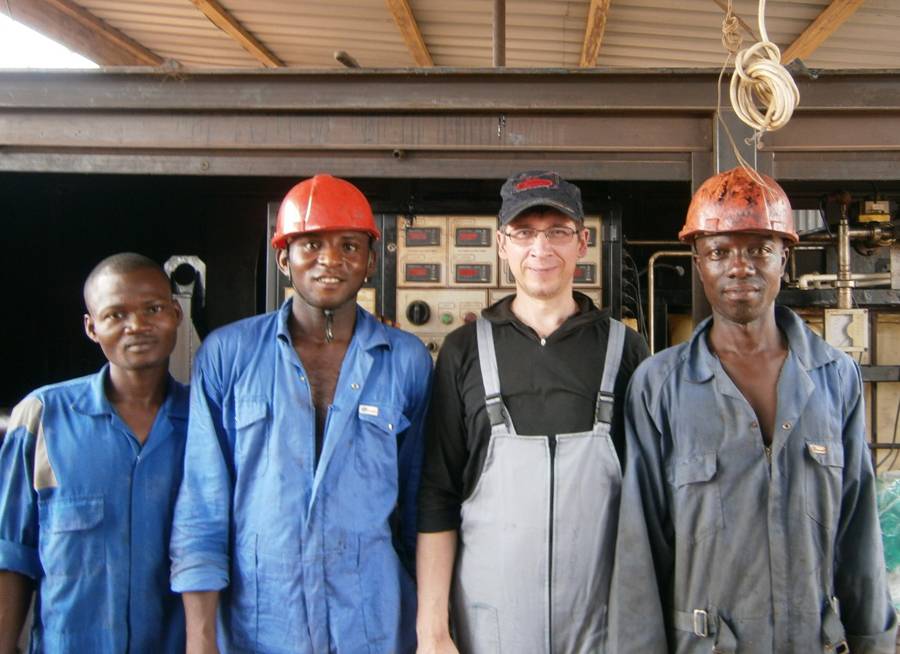

A Business Trip to Ghana

A Business Trip to Ghana In the first quarter of 2016 Globecore specialists visited Ghana. The objective of the visit was to inspect the current condition of a UVB-1 unit, which has been in operation since 2012, and to share experience to incorporate customer feedback in the company’s operations. The total length of automobile roads in Ghana is 39.41 thousandRead More

New GlobeCore service center starts operation in Houston

New GlobeCore service center starts operation in Houston Dear collegues, partners and friends! We are happy to inform you that from now on, GlobeCore services has become even more accessible and fast. A new service center in the United States has been opened in Houston, Texas, at 1750-H Dickinson Ave (FM 1266) Dickinson, TX, 77539. The phone numbers of the center are +1-713-429-1616Read More

GlobeCore Product Presentations Held in Bulgaria

GlobeCore Product Presentations Held in Bulgaria Presentations of GlobeCore bitumen emulsion equipment were held in several Bulgarian cities from 18 to 24 October 2015. Representatives of GlobeCore visited Varna, Plovdiv, Ruse and Blagoevgrad, and other Bulgarian cities. This is not GlobeCore’s first experience in working with Bulgarian colleagues. Approximately seven years ago, a 10 cubic meter per hour UVB-2 unit wasRead More

Modified Bitumen Storage SBM-30 has been Upgraded

Modified Bitumen Storage SBM-30 has been Upgraded 2015 Globecore engineering department completed upgrading and improving modified bitumen storage tank SBM-30. The result of this meticulous work is a production of the first two units of upgraded equipment in December 2015. The updated model of storage tank SBM-30 has following features: hollow part of the bottom now has a 200 mm heat insulation;Read More

Laboratory Equipment for Bitumen Emulsion ProductionIn general, laboratory equipment tries to replicate real world processes on a smaller laboratory scale. At the beginning of 20th century, it was this kind of laboratory equipment that produced the first bitumen emulsion. The majority of bitumen emulsion production methods are based on bitumen being emulsified in water. In the laboratory environment it isRead More

A New GlobeCore UVB-1 Unit Has Been Successfully Started up in Azerbaijan

A New GlobeCore UVB-1 Unit Has Been Successfully Started up in Azerbaijan On 7 February 2015, GlobeCore‘s employees finished the start up the UVB-1 unit (capacity 2 m³/hour) in Baku, Azerbaijan. Units designed for production of bitumen emulsion are in demand due to their competitive price and high quality characteristics of the final bitumen emusion product they produce. It is worth noting the following benefits of bitumenRead More

The Works Concerning Production and Supply of Equipment For the Mining Industry have been Finished

The Works Concerning Production and Supply of Equipment For the Mining Industry have been Finished At the end of 2014, GlobeCore fulfilled an order to produce a diesel-driven pumping station designed to remove water from open cast mines. The design of such equipment has been developed very thoroughly to eliminate the risk of work-related injuries. Additionally, the fact that pumps have to work under very rigid conditions must be alsoRead More

GlobeCore’s Road Building Units

GlobeCore’s Road Building Units Road-building machines are used to: lay an earth roadbed; develop traffic interchanges and sidewalks; and build traffic structures. As usual, there are many different road building units on the hi-tech market, so it can be difficult to make the right choice. That is why it is recommended to take into consideration the following criteria inRead More

Asphalt Paving Equipment

Asphalt Paving Equipment Almost every road building company has its own train of machines that is called “road construction machinery.” It consists of rather complicated industrial units that are characterized by dynamic manufacturing processes and involve complex mathematical equations. The following is a non-exclusive list and description of modern road construction equipment: An excavator is used for diggingRead More

Equipment For Road Maintenance and Repairs

Equipment For Road Maintenance and Repairs The following is the list of the units, used to maintain and repair roads: (1) recyclers for asphalt concrete; (2) asphalt cold milling machines; (3) snow ploughs; (4) joint filling machines; (5) bush cutters; (6) sand-spreading machines; and (7) bitumen emulsion units; The recyclers for asphalt concrete are meant for repairing potholes on roads madeRead More

Road Construction Equipment

Road Construction Equipment Today, scientific literature gives several alternative classifications to road construction equipment. They are all based on two main criteria – the application area and the purpose of the equipment. The following is one of the generally accepted and widespread classifications. All road construction equipment includes: machines for mining and processing rock material; machines for productionRead More

Road Construction Units

Road Construction Units It was the beginning of the 20th century when mankind first tried to mechanize the work it was performing during road construction projects. As a result of this effort, the first road construction machines began to appear. The design of a dredger ship was introduced in 1809 in St Petersburg and the design of aRead More

Bitumen Modification as a Way to Extend the Period Between Road Repairs

Bitumen Modification as a Way to Extend the Period Between Road Repairs Today, asphalt and concrete has been widely applied when paving roads and highways. Recently, there have appeared a great number of potholes because of the increased number of heavy load-carrying vehicles. Unfortunately, potholes occur all year round, but more intensively in spring. In practical terms, road pavement failures are mainly treated in a frost-free season.Read More

Bitumen-Emulsifying Equipment: Peculiarities of Usage

Bitumen-Emulsifying Equipment: Peculiarities of Usage Bitumen Emulsions Production Oil based bitumen is widely used in the road construction industry due to its excellent binding properties. Bitumen should be heated up to 100-200⁰С / 212- 392⁰F to make it liquid and only then is it mixed in with other chemical compounds. The ready mixture should be transported and applied only whenRead More

Asphalt-Emulsion Equipment

Asphalt-Emulsion Equipment Asphalt emulsion is used to make roadway surface pavements more effective and to reduce the cost of road construction projects. As compared with the traditional ways of road surface coating, bitumen emulsion allows companies to save up to 30% of bitumen and reduce energy costs by 40 %. It is worth noting that the advantagesRead More

The Presentation of GlоbeCоre Equipment in Serbia and Macedonia

The Presentation of GlоbeCоre Equipment in Serbia and Macedonia In December of 2014, a sales and marketing representative of GlоbeCоre, Antonina Sokhan, visited a number of towns in Serbia and Macedonia. She was invited by the representatives of these countries who desired to find out more about the equipment for bitumen emulsions and modified bitumen production designed and produced by GlоbeCоre. A great varietyRead More

Termoregistry Oil for Heating BitumenBitumen consists of specific substances requiring special storage and transportation conditions. In order to maintain the bitumen in good condition so that it conforms to established standards, it is necessary to carry out continuous heating of the material in specially equipped containers. Bitumen and its binder and must remain soft without stiffening and decaying thatRead More

ADVANTAGE OF WASTE TYRES USE

ADVANTAGE OF WASTE TYRES USE There are a lot of used tyres as waste material around the world. It presents a serious environmental threat. But this global problem can be successfully solved. The waste tires can be used for production of crumb rubber modified bitumen using our GlogeCore’s equipment. The Recycled Tyre Rubber can be also used for the newRead More

BITUMEN EMULSIN SPRAYER Equipment bitumen sprayer equipmentBITUMEN EMULSIN SPRAYER EQUIPMENT Dear friends! I would like to share some good news with you! Our engineers have just developed and constructed a new mobile bitumen sprayer for road construction. This sprayer has been successfully tested and put into production! bitumen sprayer equipment SPRAYER OF BITUMEN EMULSIN RBEM-2.5 TECHNICAL DESCRIPTION This sprayer unitRead More

Skid Mounted Bitumen Modification UnitThe asphalt based road systems can no longer ensure the durability of the wearing surface because of the increased amount of heavy load carrying vehicles on our roads. In the not so distant past, this problem could be solved by using crushed aggregates of average size or stone mastic asphalt. The rapid development of motorRead More

SPRAYER OF BITUMEN EMULSIN RBEM-2.5Dear friends! I would like to share some good news with you! Our engineers have just developed and constructed a new mobile bitumen sprayer for road construction. This sprayer has been successfully tested and put into production! SPRAYER OF BITUMEN EMULSIN RBEM-2.5 TECHNICAL DESCRIPTION This sprayer unit is designed to diffuse hot bitumen emulsion forRead More

The First in Tanzania Bitumen Emulsion Production Plant was Successfully Started Up

The First in Tanzania Bitumen Emulsion Production Plant was Successfully Started Up On October 4, 2014, there was a ceremonial opening of the first in Tanzania bitumen emulsion plant, fully equipped with GlobeCore equipment. The gravity of the occasion was evidenced by the fact that the vice-president of the rural and urban road construction industry of the United Republic of Tanzania – Hassan Matimbe – was presentRead More

Oil bitumen heatingBitumen is a material requiring special storage and handling conditions. There are standards of bitumen storage, requiring constant bitumen heating in specially equipped vessels. Bitumen is a binding material and must stay that way, without breaking into water and bitumen, which may occur if bitumen emulsion is stored incorrectly. Bitumen storage tanks can be vertical orRead More

Bitumen emulsification equipment

Bitumen emulsification equipment Water bitumen emulsion is a highly dispersed liquid material of dark brown color, made by atomizaion of bitumen in water solution of an emulsifier. Bitumen emulsion is produced in special dispersers, ultrasonic homogenizers and colloid mills. These machines vary in the method used for emulsification of the raw material and the quality of the product.Read More

United Arab Emirates: GlobeCore moves to the new office

United Arab Emirates: GlobeCore moves to the new office Dear customers! We are glad to inform you about the moving of our office in the United Arab Emirates. Henceforth we are available at: Globecore FZE Al Jazeera Al Hamra, P.O. Box 31291, RAKIA Business Centre 5, Building No. A4, Office No. 205 Ras Al Khaimah United Arab Emirates. We look forward to seeing you!Read More

The plant for the preparation of the water phase has been started up in Thailand

The plant for the preparation of the water phase has been started up in Thailand In the end of June 2014 GlobeCore completed all planned commissioning operations and personnel training in Thailand. A 20 cubic meter per hour UVB water phase preparation unit for bitumen emulsions was supplied to this country. Bitumen equipment made by our company is optimized for the required production capacity. The bitumen emulsion can be usedRead More

The ptoject for delivery UMBP-22P was implemented in Vietnam

The ptoject for delivery UMBP-22P was implemented in Vietnam In end end of April, GlobeCore has complete a project involving supply of UMBP-22P to Vietnam. The unit was commissioned by GlobeCore’s staff. The UMBP-22P is designed for modification of bitumen by polymer. One of the possible modification products is bitumen-polymer binding, which is widely used in preparation of asphalt road top, surface treatment ofRead More

Bitumen emulsion storage tankThe emulsion is a rather specific material, requiring special attention and adherence to standards both at the stage of production, and transportation and storage. In storage the emulsion requires special temperature, protection from direct sunlight and monitoring of the material in storage. Water-bitumen emulsion is a highly dispersed dark brown liquid, made by special plantsRead More

Bitumen emulsion storage and transportation technology

Bitumen emulsion storage and transportation technology Bitumen is supplied to road construction companies mostly by oil refineries, located in large industrial centers, which can be located far from the areas of consumption. Bitumen production is seasonal and peaks in spring and summer. All of the above leads to the need of transporting the binding over significant distances, stockpiling and storage andRead More

The secrets of German roads – emulsifield bitumen and traction

The secrets of German roads – emulsifield bitumen and traction It is well known that investment into maintenance and servicing of roads in the West is several times that of the eastern countries and the nations of the former USSR. For example, a nation with the best and most expensive roads, Germany, spends around US$ 3.9 million per 1 kilometer of highway, which in RussiaRead More

Technology: General ConditionsThe acceptance of our quotation implies the acceptance of the following terms and conditions. Modifications of or deviations from them must be agreed in writing. 1. VALIDITY Unless previously withdrawn, our quotation is open for acceptance within the period stated therein, or when no period is stated within ninety days only from the date thereof.Read More

LABORATORY SCALE FOAMED BITUMEN PLANT type UVB-LThe laboratory scale foamed bitumen plant type UVB-L is designed for obtaining foam bitumen samples. The unit can be operated by organizations, producing asphalt concrete mixtures, as well as road construction and repair organizations. The unit is designed for indoor operation. The design of the unit ensures normal operation in ambient temperatures from +5 0СRead More

Bitumen Modification Equipment UMB-4APPLICATION The bitumen modification unit UMB-4 (referred to as the unit) is designed to produce polymer-modified bitumens. The bitumens are in accordance with all applicable standards. Modified bitumen is used in road and bridge construction and repair. The unit can be used by asphalt and road top producers, roofing and building hydro-insulation companies. The unitRead More

Bitumen Emulsion System UVB-LApplication Water-bitumen/ laboratory system UVB-L is designed:: to prepare laboratory parties of bitumen emulsions; to develop the recipe of water-bitumen emulsion depending upon the solution of bitumen emulsion components likewise the area of application. The construction of the machine provides its up state when operating complies under the temperature from 5C to40C Specifications № Parameters Value 1Read More

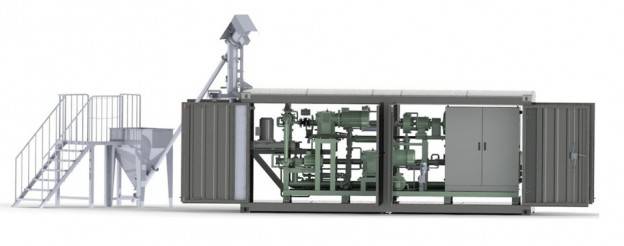

Containerized Bitumen Emulsion Plant UVB-1

Containerized Bitumen Emulsion Plant UVB-1 Application Bitumen-emulsion system UVB-1 (water phase) is designed to produce anion and cation bitumen emulsions that in road construction are used: to prepare old road base for asphalt-concrete; for surface treatment of the roads; for making thin protective coatings; for patch road repairs; to ensure water-tightness of buildings and other constructions; for construction and repairingRead More

Asphalt Bitumen emulsion plant type UVB-1 (containerized) (production capacity 10 m³/h)Bitumen emulsion plant UVB-1 is designed to produce bituminous emulsions of anionic and cationic type: to prepare old road base for asphalt-concrete; to prepare cold asphalt-concrete mixtures; for surface treatment of roads; for making thin protective coatings; for patch road repairs; to ensure water-tightness of buildings and other constructions; for construction and repairing of soft roofs. Read More

Bitumen Emulsion System UVB-14Applicatuion: Bitumen-emulsion system UVB-14 (water phase) is designed to produce anion and cation bitumen emulsions that in road construction are used: to prepare old road base for asphalt-concrete; to prepare cold asphalt-concrete mixtures; for surface treatment of the roads; for making thin protective coatings; for patch road repairs; to ensure water-tightness of buildings and otherRead More