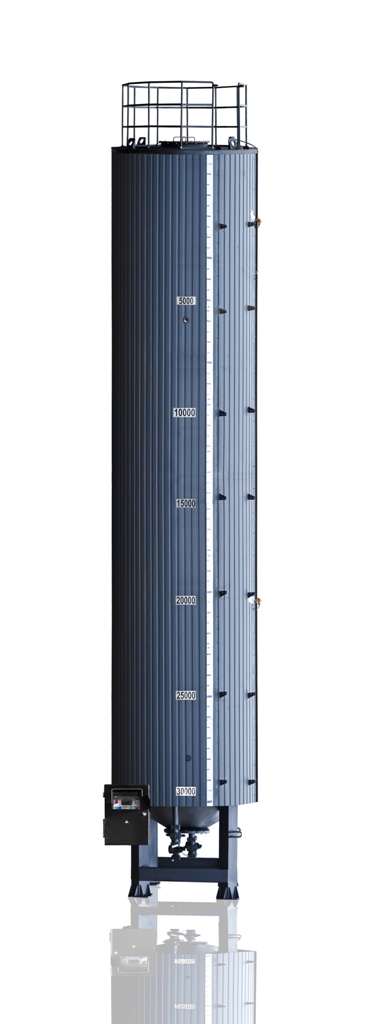

Modified Bitumen Storage Tank USB-4 (30)

We would like to bring USB-4 (30) storage tanks to the attention of companies engaged in manufacture and repair of asphalt pavements, asphalt roads, waterproofing buildings, constructing soft roofing and other works requiring modified bitumen.

Application of bitumen modified by polymers expands operational temperature range of heat and cold endurance, as well as ensures reliability and durability of buildings and concrete asphalt coatings.

To achieve these results, there is a strict technology of production and storage before it is used.

Modified bitumen storage tank USB-4 (30) is a heat insulated tank for storing polymer-modified bitumen. This type of equipment is mass-produced as well as custom designed by GlobeCore. At customers’ request, GlobeCore produces tanks of any volume and configuration. Mass-produced storage tanks for modified bitumen can be purchased directly from warehouses. Custom designed modified bitumen tank is produced within 45 working days.

Our specialists help you to select, install and set it up for exploitation bitumen storage tank. Due to widespread network of representative offices and service centres we can provide customer’s support almost all around the world.

GlobeCore modified bitumen storage tank USB-4 answers to all your needs, if you are:

- Owner of a road-construction company, looking for effective solutions bringing stable profit;

- Purchasing manager, searching for high quality at best price, building good supplier relationships. GlobeCore works with companies and enterprises in more than 70 countries in the world;

- Maintenance superintendent, ensuring safe working condition of road works and repairs done on schedule;

- Road worker executing road repairs and maintenance on time.

Order storage tanks SBM-30 for bitumen bases and ensure quality of modified bitumen!

GlobeCore modified bitumen storage tank USB-4 (30) with help you solve all Your tasks:

- rise heat and cold endurance of roadway surfacing and other construction based on modified bitumen;

- ensure reliability and durability of constructed roads and roofing;

- raise rate and efficiency of application of road mixes.

If you answers were “Yes” – we are on the same page!

Technical specifications of modified bitumen storage tank USB-4 (30)

| № | Parameter | Value |

| 1 | Total storage capacity, m3, min | 32 |

| 2 | Operational capacity, m³, min | 30 |

| 3 | Power voltage, V | 380 |

| 4 | AC frequency, Hz | 50 |

| 5 | Power consumption, kW | 30 |

| 6 | Agitator rotation frequency, rpm | 400 |

| 7 | Effective surface of heating unit, m². | 22 |

| 8 | Heating capacity, l | 250 |

| 9 | Heat insulation depth, mm | 200 |

| 10 | Dimension for transport, mm, max: | |

| -length | 12000 | |

| -width | 2400 | |

| -height | 2550 | |

| 11 | Overall dimensions, mm, max: | |

| -length | 2850 | |

| -width | 2800 | |

| -height | 12000 | |

| 12 | Weight, kg, max | 8500 |

| 13 | Weight when loaded, kg, max | 40000 |

| 14 | Design weight of support block, t | 10 |

| 15 | Temperature drop of bitumen when filling a storage tank at ambient temperature 5ºС, per day | 1-2 |

To start GlobeCore equipment operating at your site?

1) Please contact us by email or by phone and we will discuss your order together;

2) We will offer you a range of models and prices, and advise on delivery time.

3) If required – we can meet at our facilities.

Advantages of GlobeCore modified bitumen storage tank USB-4 (30):

- structural design of a tank with downwards pointing conic bottom and 200 mm heat insulation thickness reduce heat loss;

- roof shape prevent rain water accumulation;

- bitumen level at tank filling is controlled;

- bitumen temperature inside a tank is controlled;

- sensor readings are shown on screen in control cabinet;

- overflow pipeline allows preventing spillage of hot bitumen in emergency situations;

- competitive price.