The asphalt based road systems can no longer ensure the durability of the wearing surface because of the increased amount of heavy load carrying vehicles on our roads. In the not so distant past, this problem could be solved by using crushed aggregates of average size or stone mastic asphalt.

The rapid development of motor vehicles has made the road builders take more effective measures to make the road surface more resistant to (1) high temperature extremes; (2) cracking at low temperatures; (3) surface scaling; (4) potholing; and (5) aging.

It has been known that the quality of a bitumen-concrete mixture is largely determined by the quality of the bitumen binders.

It was therefore, the researchers and road builders that decided that it would be reasonable to substitute polymer modified bitumen for traditional bitumen. This tendency first appeared in the 1960s. Since then, there has been an intensive, but, unsystematic development of modified bitumen.

The use of different polymers and a constant search for new ways to connect them with bitumen were the main tendencies of this development. A clear theory of bitumen modification first appeared only at the end of the 20th century.

The theory states that the most effective modifiers are thermo-elastoplast polymers and that the substitution of modified bitumen for traditional bitumen will benefit the service life of road surface pavement materials.

GlobeCore has developed skid mounted bitumen modification units, designated as UBV-2, to produce high quality modified bitumen. These units are made of separate standard blocks that can be replaced or added to meet the individual customer’s order and needs. It helps to find a solution to any technological problems.

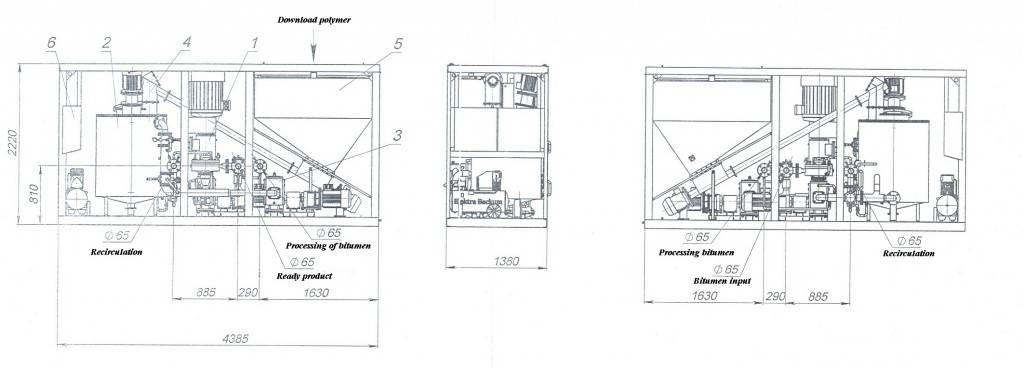

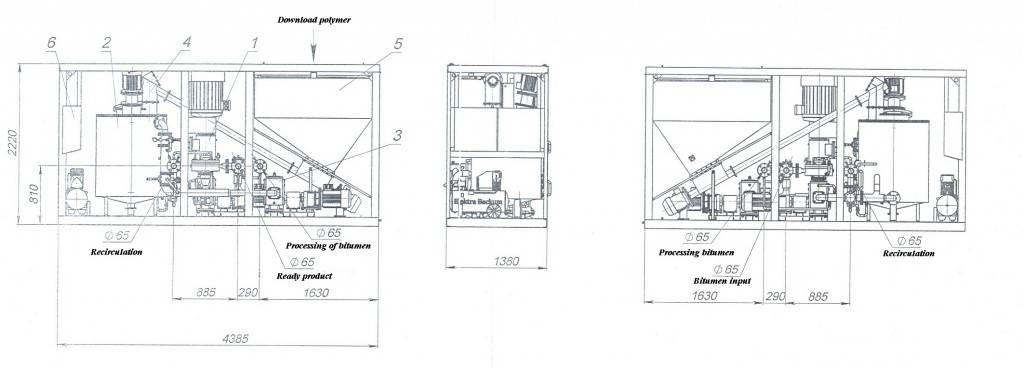

The main unit for modified bitumen production (Fig.1) consists of:

(1) colloid mill; (2) premixing container for “SBS”(styrene-butadiene-styrene) and bitumen; (3) bitumen supply pump; (4) screw-type feeder of “SBS”; (5) tank-receiver for “SBS” with mounted load cells, and (6) a control systems.

Fig.1. The main unit for modified bitumen production

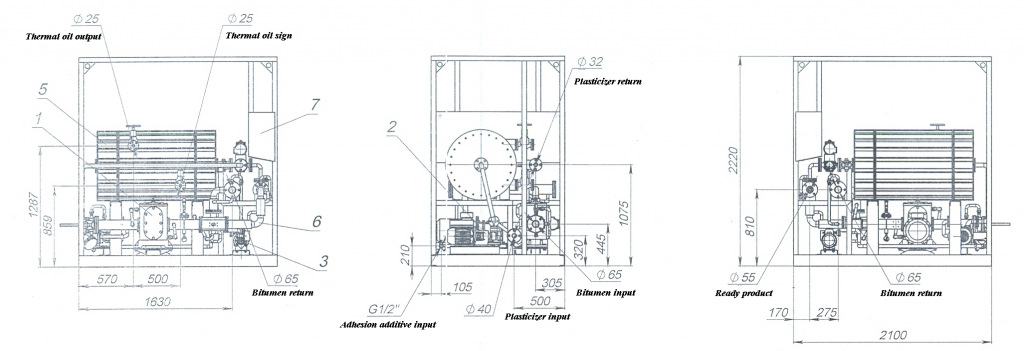

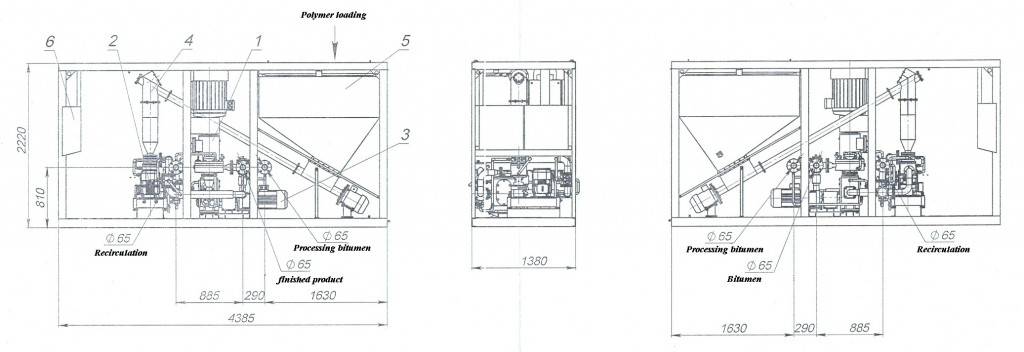

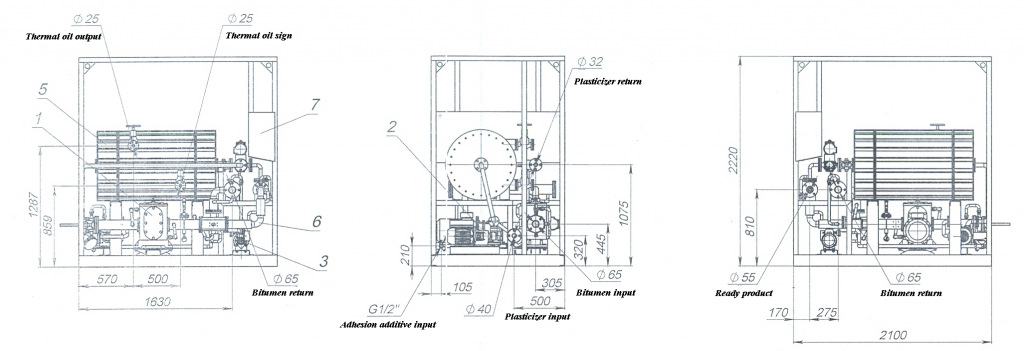

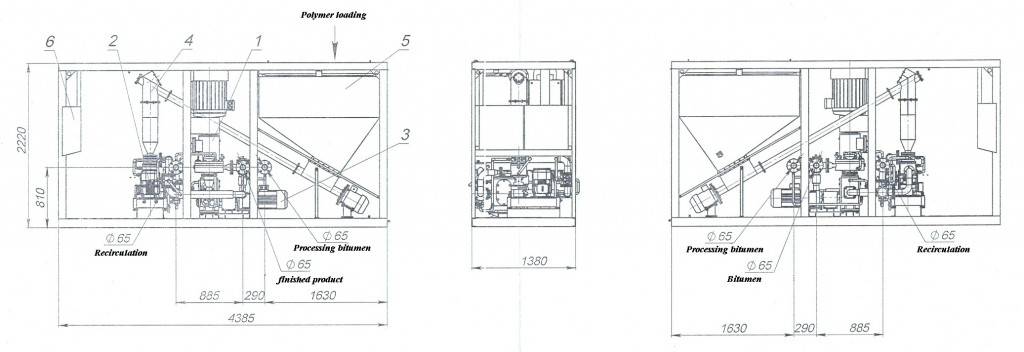

All of these units are mounted in spatial relays that allows them to be transported by any means of transport. Additionally, these units can be completed with a “Block of plasticizer and adhesive additive supply” (Fig. 2) and (or) “Block of bulk materials input” (Fig. (3).

Fig.2. Block of plasticizer and adhesive additive supply

Fig.3. Block of bulk materials input

“The block of plasticizer and adhesive additive supply” is an autonomous unit consisting of 3 pumping points: (1) bitumen; (2) plasticizer (3) adhesive additive; (4) an injector mixer; (5) a heat-transfer device; (6) a piping system; and (7) a control system.

“The block of bulk materials input” is also an autonomous unit consisting of: (1) a colloid mill; (2) an input bulk materials unit; (3) bitumen supply pump; (4) screw-type feeder; (5) tank-receiver of bulk materials with mounted load cells; and (6) a control system.

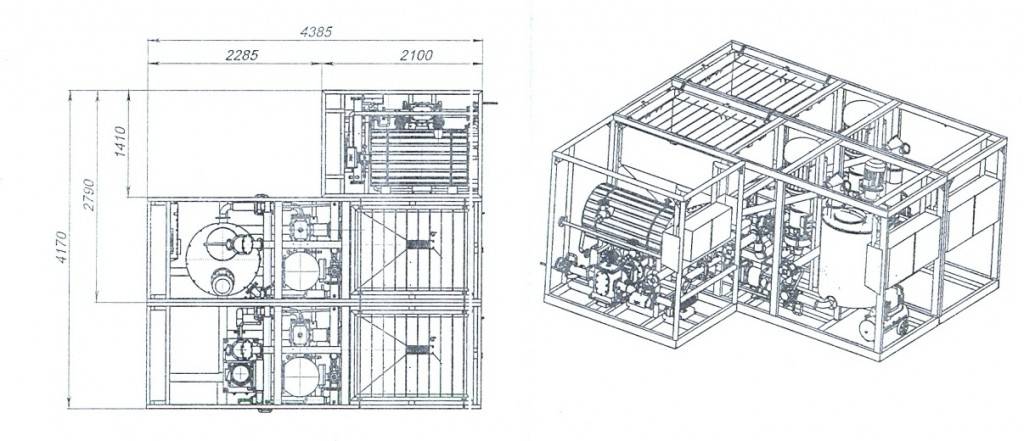

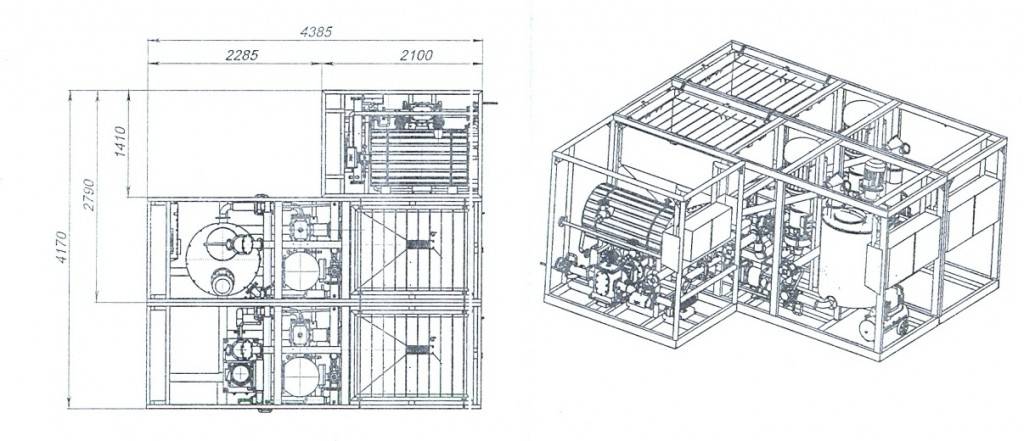

The blocks, described above, can operate independently as well as as a part of a set (Fig.4).

Fig.4. Skid Mounted Bitumen Modification Unit

This set may also be equipped with (1) modified bitumen storage tanks with volume of 15 and 30 m³; (2) container-type storage tank with volume of 32 m³; (4) an oil heat generator with capacity of 70-500 kW (kilowatt) that operates on any kind of fuel or electricity.

The set may be equipped with pumping stations, designed to input and output of modified bitumen to meet the customer’s order.

All the units have reverse bitumen pipes that allow the operators to rinse equipment with clean bitumen when the main works are done. Modular design of this equipment allows a quick mounting and dismounting when moving to another site.