Modified Bitumen Equipment

|

USB-3 Bitumen modification unit 16 m3/hour production capacityThe USB-3 unit is engineered for the continuous production of modified bitumen, boasting a rated capacity of 12 cubic meters per hour. In the modification process, the USB-3 unit accommodates various modifiers available today, including crumb rubber, special additives, and SBS-polymers in granular, powdered, or liquid form. This versatility extends to facilitating the implementation of new formulations involving adhesion additives and plasticizers. |

|

USB-3 Continuous Bitumen Modification Unit (12 m3/hour)Unit is designed for preparation of modified bitumen by adding polymers. The unit grinds and homogenizes polymers in bitumen, reducing PMB preparation time. The unit can be used at road top production and repair, water-proofing material production and soft roofing material production facilities. |

|

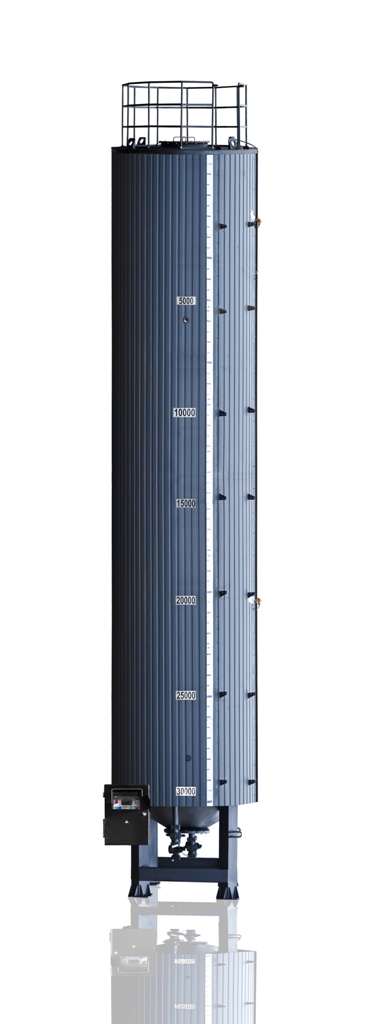

Modified Bitumen Storage Tank SBM-30Modified bitumen storage tank USB-4 (30) is a heat insulated tank for storing polymer-modified bitumen. This type of equipment is mass-produced as well as custom designed by GlobeCore. At customers’ request, GlobeCore produces tanks of any volume and configuration. |

|

Modified Bitumen Collection Tank SBM-15GlobeCore manufactures SBM-15 storage tank for companies in road construction and repair, waterproofing buildings as well as soft roofing. SBM-15 is a heat-insulated tank designed for storage of polymer modified bitumen. |

|

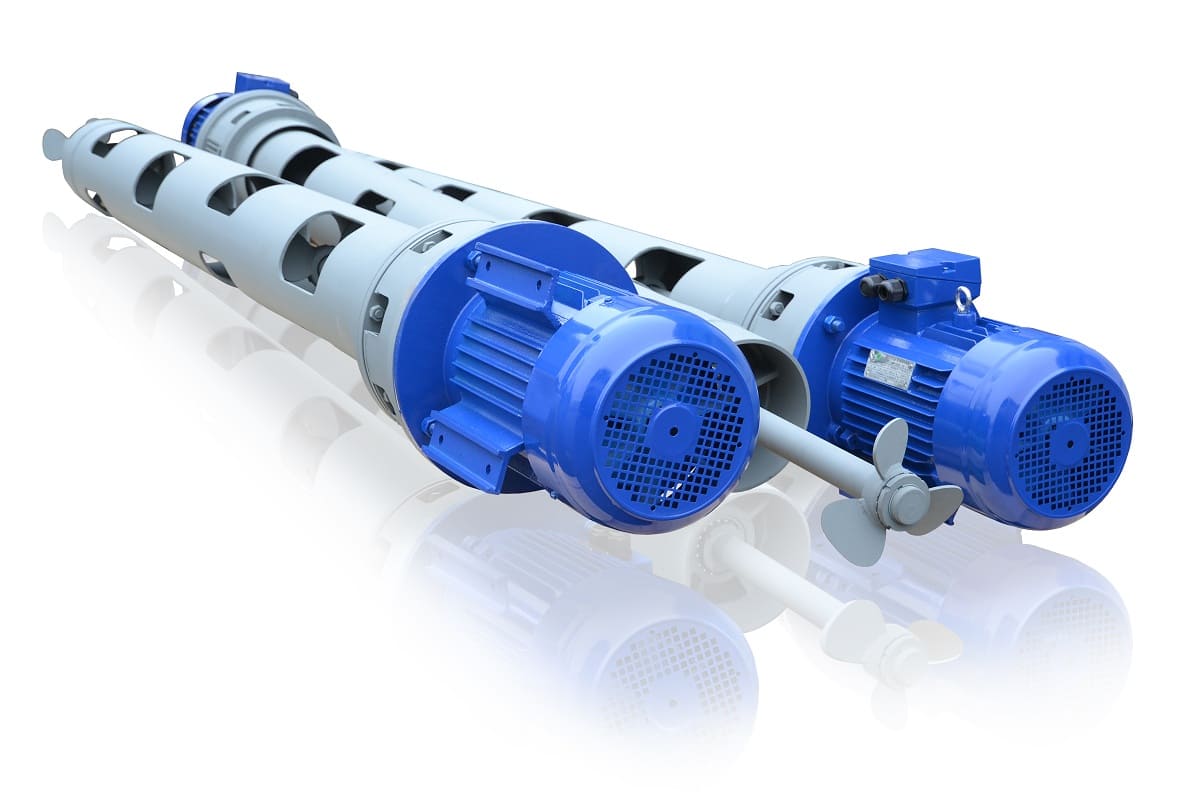

Impeller Stirrer USB-6The USB-6 impeller stirrer is specifically engineered for effectively mixing liquid layers within containers or tanks, serving a variety of applications including the production of different emulsions and suspensions, such as antiseptics and disinfectants. |